HEALTH, SAFETY AND ENVIRONMENT

Our mission is to deliver exceptional facilities to our clients through construction projects completed with zero accidents or injuries.

To achieve this, we implement a comprehensive safety program that includes:

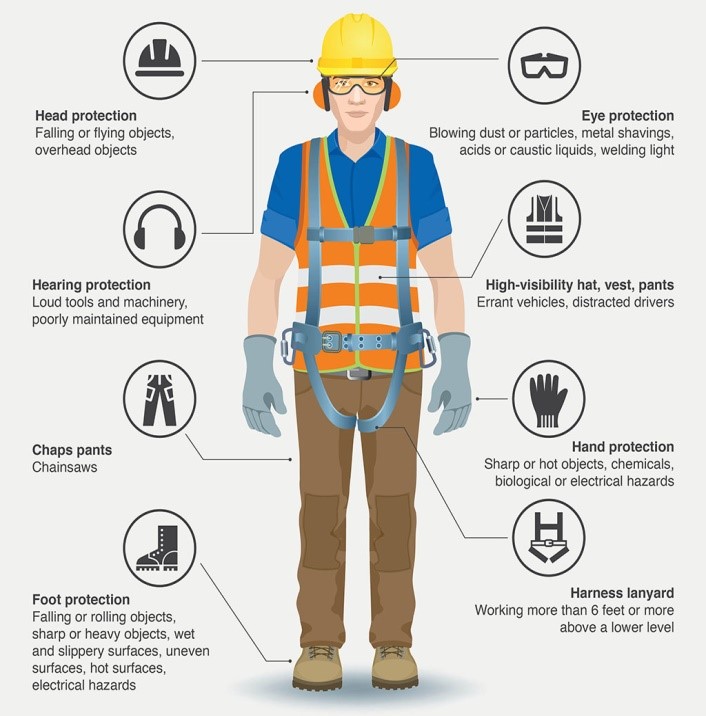

Personal Protective Equipment (PPE): Providing all workers and visitors with appropriate PPE, including goggles, helmets, gloves, ear protection, boots, and high-visibility vests or suits, to minimize exposure to worksite hazards.

Safety Signage and Training: Conducting specialized training to ensure all personnel understand and recognize safety signs (prohibition, mandatory, warning, safe condition, and firefighting equipment). Strategically placing these signs throughout the site to enhance awareness and communication.

Site Cleanliness and Housekeeping: Implementing daily cleaning protocols to remove debris, dust, loose nails, and stagnant water, preventing slips, trips, and other hazards.

Tool and Equipment Management: Training personnel on proper tool storage and handling, ensuring tools are not left lying around and that electrical tools are unplugged when not in use. This prevents damage and injuries, while also improving site organization.

Correct Tool Usage: Emphasizing the importance of using the correct tools for each task to prevent accidents caused by misuse or makeshift solutions.

Emergency Response Planning: Providing thorough training on emergency response procedures for natural disasters, fires, hazardous material spills, and other incidents. Establishing a dedicated emergency response team to manage crises, answer questions, and report potential hazards, quality issues, or near misses.

Engineering Controls: Implementing engineering controls, such as barriers, fences, and safeguards, to isolate personnel from hazardous areas, including those with high-voltage electricity or toxic fumes.

Pre-Work Equipment Inspections: Conducting practical training to ensure all tools and equipment are inspected for defects or damage before use.

Defect and Near-Miss Reporting: Training workers to promptly report any defects or near misses. Early reporting allows management to address issues quickly, preventing escalation and potential accidents.

Our Clients